Invented in the late 1700s, the hydraulic press has been used to mold, compress, crush, and shape metallic objects for many years. With advancement in technology, its performance has improved and its features have undergone a major "facelift" which in turn has given the hydraulic press a more competitive edge as compared to its cousin, the mechanical press.

Powered by hydraulic pump, it offers a wide range of flexible measures which in turn allow adjustments to be made with each press. This distinct feature makes the hydraulic press more suitable for jobs that require specific detailing. Adding to this uniqueness is the fact that it delivers a full press, as opposed to a mechanical press, which will deliver most of its force within a smaller range on the bottom of the stroke.

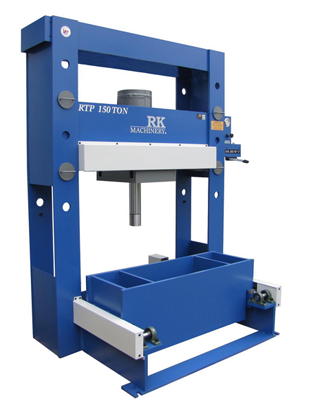

The shop press occupies 50% less space as compared to the mechanical press. This in itself is an economic advantage in the long term. Hydraulic presses allow for the use of a smaller surface but with increased pressure, therefore making it valuable and cost effective in the sense that production expenses are lower as compared to the mechanical press.

Hydraulic presses, also known as

shop presses, are able to do a lot more than the mechanical press. It can mold, shape and also press without needing any expensive restructuring. Therefore it can be used for many different jobs producing a wide range of products. Also considering the fact that it has a higher functioning speed which is about 200 strokes in a minute makes it a high quality press that allows for more to be accomplished within a shorter period of time, therefore eliminating time wastage.

Hydraulic presses are much more manageable in terms of controlling its power as opposed to the mechanical press. This allows for switching functions to suit the work that is being done. If one needs high force and power, they are able to adjust the settings without a whole lot of altercation. The fact that switching from high to low force is attainable almost makes the shop press seem like a two-in-one press.

Choosing a hydraulic press over the mechanical press gives the user an upper hand in that you not only save maintenance cost in the long term but also you are able to produce better quality products, save time and a whole lot of energy. Before investing in one, it is important to learn how to properly operate it and what safety measures to implement in order to get the most value for your money while avoiding accidents.

Français

Français